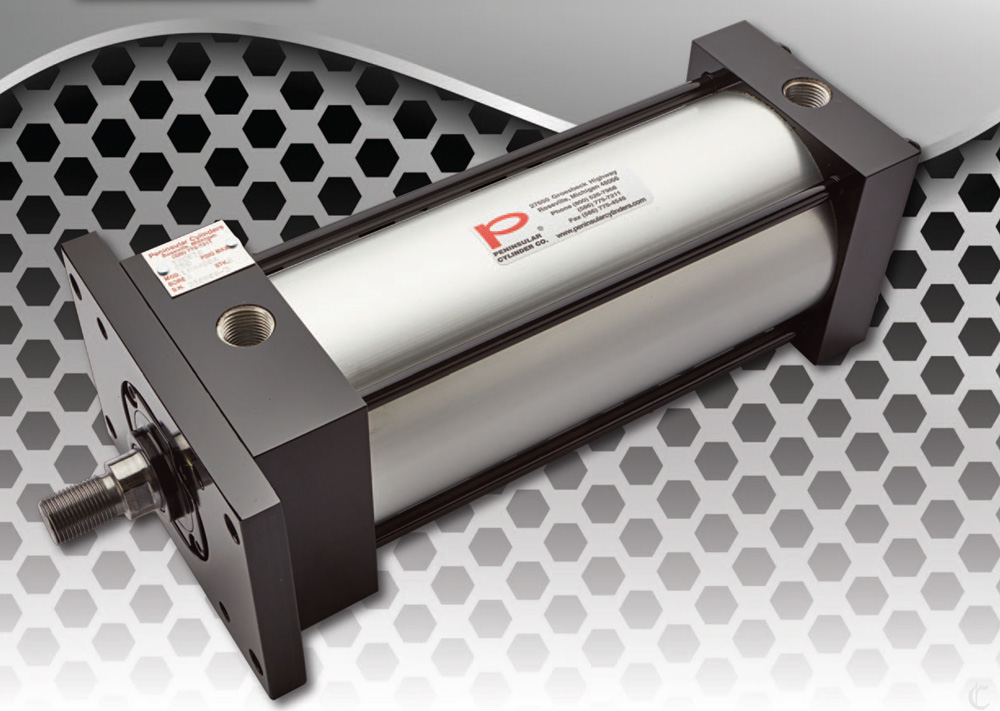

Peninsular Air Cylinder – HP Series

Steel • Heavy Duty • 3,000 PSI

NFPA Interchangeable

- Features & Benefits

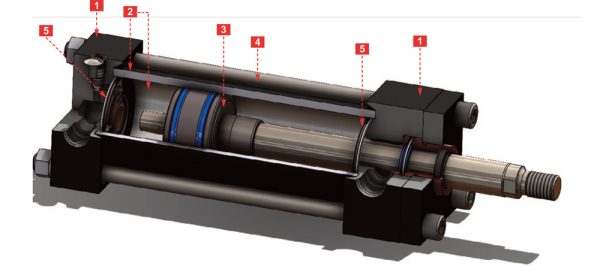

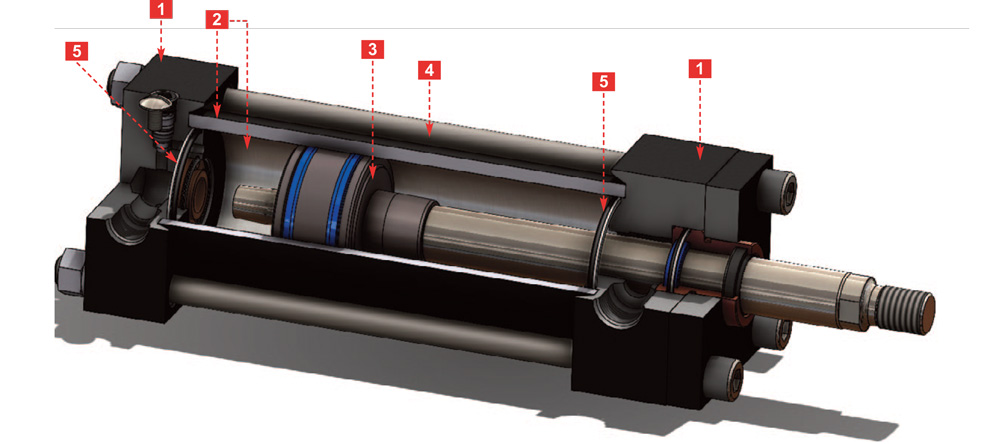

- Heads & Caps

Square, precision made carbon steel end covers. Precision machined for concentricity of tube, bearing, cushion and piston rod. Chamfered grooves allow fast and easy positioning of cylinder tube over the tube seals. Can be made proximity switch ready to accept same probe-length switches at each end without spacers.

- Cylinder Tube

Heavy wall seamless D.O.M. steel material (1020 to 1026). Precision honed to 10/15 micro inch finish. Tubing has superior concentricity and a high degree of uniformity in wall thickness.

- Piston

One-piece fine grained ductile iron piston is threaded onto piston rod and held in place with thread locker and staked to a secure position. Wide piston bearing surface reduces bearing loads and assures low wear and low friction to the piston seals and tube ID. An O-Ring with two backups are used to seal the piston to the rod, which prevents fluid leaks from bypassing the piston. Piston wear band optional.

- Tie Rods

Made from 100,000 psi minimum yield, stress-proof, medium carbon steel with rolled threads at each end. Grade 8 hex nuts with washers provide maximum strength for cylinder assembly.

- Tube Seals

90 durometer Buna-N Nitrile O-Rings are seated into grooves in both the head end and cap end covers. When combined with accurately torqued pre-stressed tie rods, proper O-Ring placement at the ID of the tube and confinement of the tube OD, seal extrusion and fluid leakage under pressure is prevented.

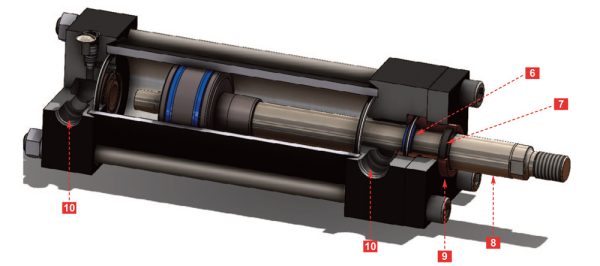

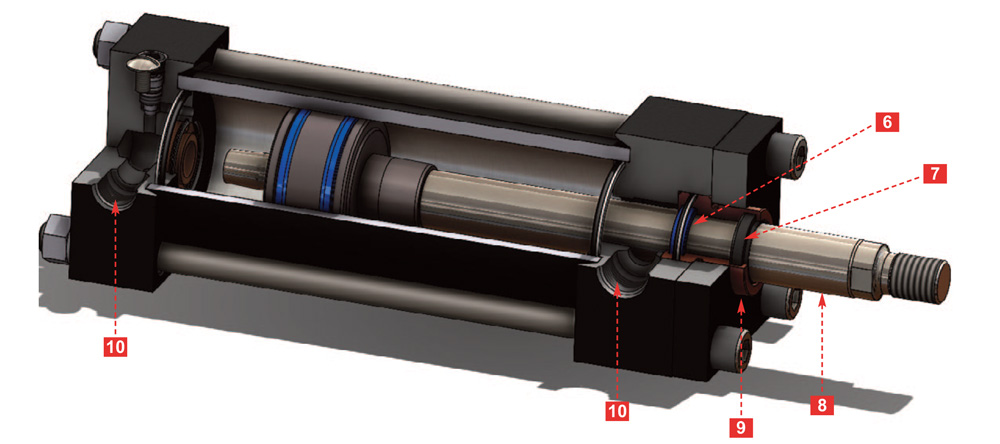

- Rod Seal

The asymmetrical twin lip Urethane rod seal U-cup provides positive static and dynamic sealing at both low and high pressures.

- Rod Wiper

Urethane H type wiper seal keeps contaminants off the rod and provides additional sealing beyond rod seal. Severe external conditions could require the addition of an optional metallic rod scraper installed ahead of the rod wiper to effectively provide dual protection from the elements. Guards against dust, dirt and grit from entering the bearing cartridge and cylinder, which significantly extends the cylinder life.

- Piston Rod

85,000 psi minimum yield strength chrome plated steel with core hardness of Rc 28-34. Rod is hard chrome-plated (.0003/.0005 thick) and polished to 12/15 micro inch finish. Solid male threads contain a radiused undercut. Resists wear and provides positive connections to existing machine components. Solid male threads include a radiused undercut to minimize stress risers.

- Bearing Cartridge

Floating, self-aligning bearing cartridge is made from grade 65-45-12 ductile iron. Cartridge is retained by cap screws and plate providing for strength and shock resistance. 90 durometer Buna-N O-Ring with backup ring on the cartridge O.D. prevents extrusion and fluid leakage around the outside of bearing cartridge. Float condition minimizes piston rod misalignment by reducing side loading.

- Ports

NPT or SAE O-Ring ports are to be identified at time of order. Optional port sizes include flange ports, metric ports and oversized ports. Universally adaptable to any hose or fitting.

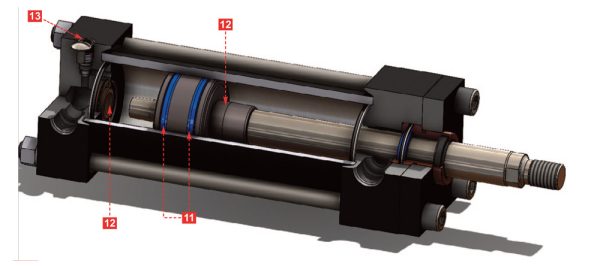

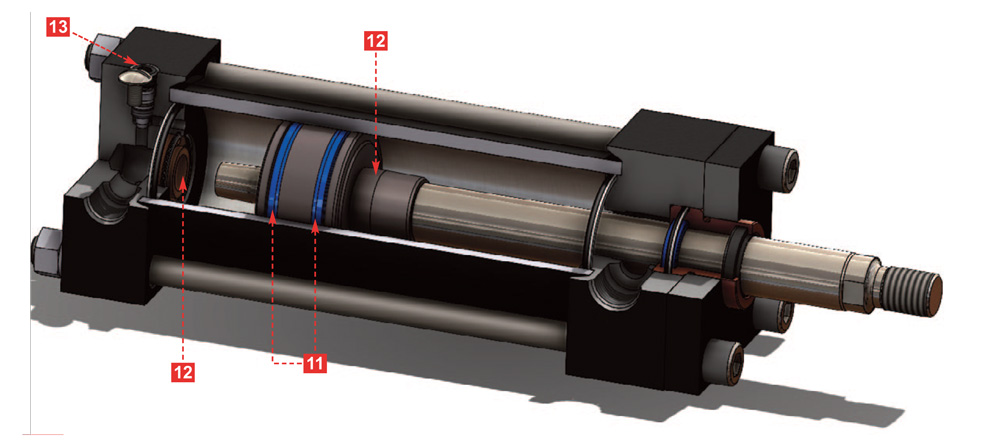

- Piston Seals

Asymmetrical Urethane U-Cups with seal material options available including backup rings. Hydraulic X-Pac type seals are standard for 10” bore and larger cylinders. X-Pac seals may also be used on smaller bores. Step cut cast iron piston rings & high load piston seals are also available.

- Cushions

Floating ductile iron rod cushion collar on head end. The cap cushion is a Ductile iron floating, check-type seal insert held captive by a retaining ring in the rear end cap. Ball checks are provided at both ends for rapid breakaway out of the cushion and the ball check screws are flush with the end caps. Cushions are optional but ultimately help prevent cylinder failure, due to fatigue, resulting from the piston slamming into cylinder end caps. A reliable floating cushion system provides for smooth action and eliminates binding conditions, which can cause sudden failure.

- Cushion Adjustment Screw

Steel needle valve with 90 durometer Nitrile O-Ring and backup ring. The captive adjustment screw can be locked in place and is flush with the end cap. The backup ring behind the O-Ring prevents fluid leakage around the adjustment screw, The cushion design allows fine adjustment of cushioning speed. Captive screw assures user safety.

- Optional Air Bleed System (Not Shown)

Manual air bleed plug is located on the cylinder tube.

- Optional Rod Drain Back System (Not Shown)

Drain feature is an additional groove cut into the front end of the bearing cartridge, between the rod wiper and rod seal, that drains off any accumulation of fluid between the seals. A cartridge drain port is located on the cartridge retainer plate for a user-installed drain line back to the reservoir. Captures hydraulic fluid and drains it back to the reservoir. This minimizes the slow weepage of hydraulic fluid through the rod wiper onto the piston rod. By capturing it and redirecting it to the tank..