Peninsular Air Cylinder – MH Series

Steel • Heavy Duty • 250 PSI

Pre-Lubricated • NFPA Interchangeable

- Features & Benefits

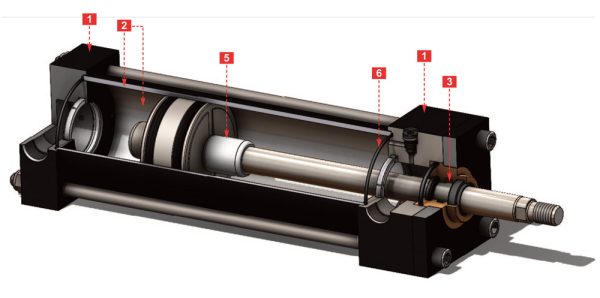

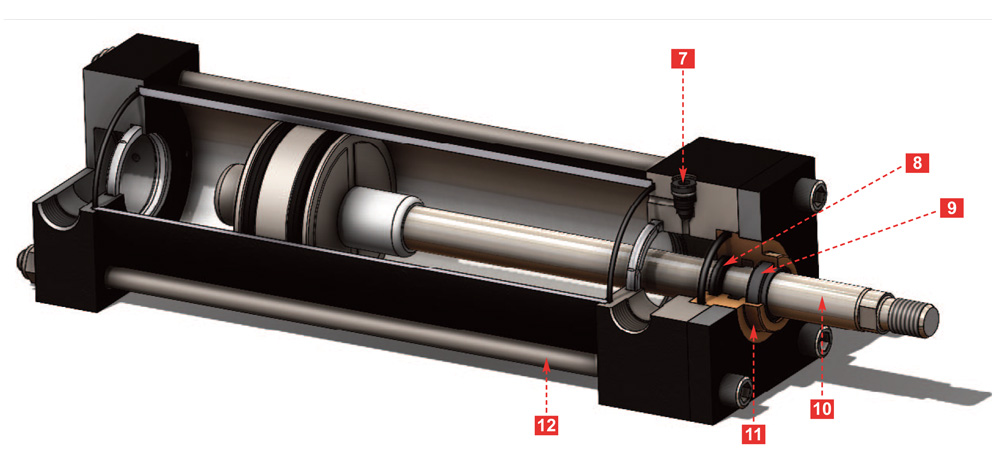

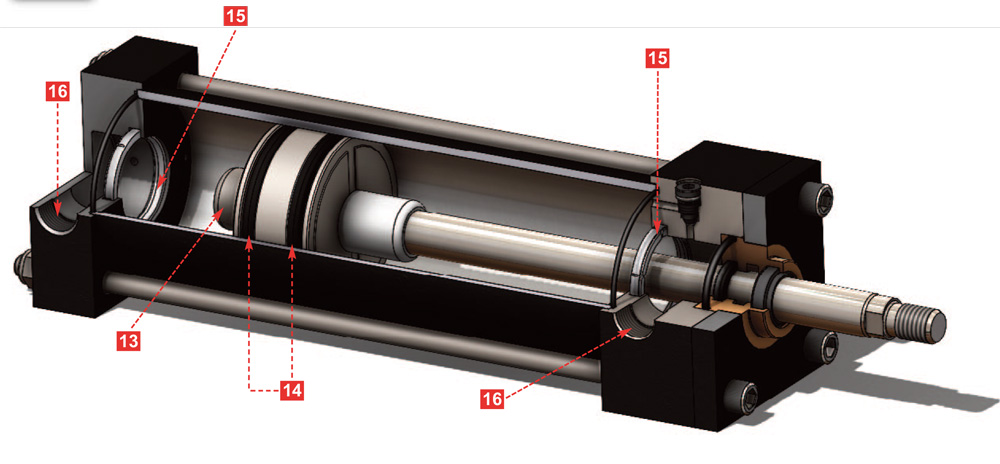

- Heads & Caps

Square, precision made carbon steel. Can be made proximity switch ready to accept same probe-length switches at each end without spacers. - Cylinder Tube

O.M. seamless 1020 to 1026 steel; precision honed to 10/15 micro inch finish; hard chrome plated .0003/.0005” thick on ID. Chrome Plating reduces wear on piston seals and tube I.D. surface. Hard chrome plated I.D. provides corrosion resistance and minimizes tube scoring. - Lubrication Reservoirs

Located in the bearing cartridge. Provides effective way of metering maximum amount of lubricant to all areas over a long time period.

Not subject to air turbulence and contamination. - Lubricant (Not Shown)

Teflon™ based grease. Long lasting lubrication of piston seals, inner cylinder wall surface, bearing cartridge ID, rod seal & rod wiper. - Piston

One-piece fine grained ductile iron piston threaded onto piston rod staked and held in place with thread locker. Affixed onto

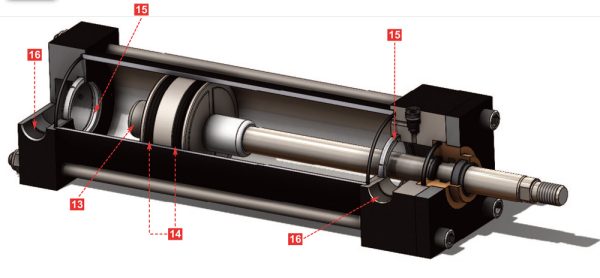

piston rod with minimum undercut providing maximum strength. Aluminum piston required for magnetic piston sensing – see #18. - Tube Seals

Nitrile axial placed O-Rings. When combined with accurately torqued tie rods, prevents extrusion of seal & air leaks under pressure. - Cushion Adjustment Screw

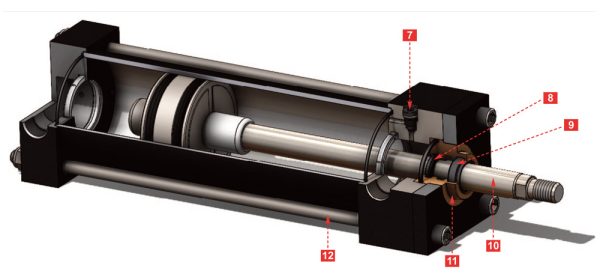

Steel needle valve with Buna-N O-Ring sealed screw, held captive with locking snap ring. Accurate fine adjustment of cushioning

speed; no air leakage and safe for all users due to internal captive screw. - Rod Seal

80 durometer, rounded lip, prelubricated, carboxylated nitrile cup style. Disperses grease throughout ID of rod cartridge extending

seal life within. Resists abrasion; significantly increases life and prevents leakage around piston rod. - Rod Wiper

Urethane H type wiper seal resists contaminants on the rod and provides additional sealing beyond rod seal. Severe external conditions

could require the addition of an optional metallic rod scraper installed ahead of the rod wiper to effectively provide dual protection from the

Prevents dust, dirt and grit from entering the bearing cartridge and cylinder, which significantly extends the cylinder life. - Piston Rod

85,000 psi minimum yield strength chrome plated steel with core hardness of Rc 28-34. Rod is hard chrome-plated (.0003/.0005 thick) and polished to 12/15 micro inch finish. Solid male threads contain a radiused undercut. Resists wear and provides positive connections to existing machine components. Solid male threads contain a radiused undercut to minimize rod end breakage. - Bearing Cartridge

Floating, self-aligning ductile iron with internal lubrication reservoir. Retained by plate with cap screws; strong and shock resistant. A Buna-N O-Ring located around the cartridge OD prevents leakage. Float condition minimizes piston rod misalignment by reducing side loading. ID of bearing cartridge, rod seal and rod wiper lubricated on each stroke, reducing wear. Easily removed for maintenance without special tools

to disassemble cylinder. - Tie Rods

Made from 100,000 psi minimum yield, stress-proof, medium carbon steel with rolled threads at each end. Provides maximum strength for connecting cylinder mounts and used with lock nuts to prevent loosening in service. Accurate torqueing prevents leaks at tube seals. - Cushion Hubs

Steel with 8/12 micro inch finish RMS. Black oxide to prevent rusting and corrosion. Steel material permits the use of in-port cylinder

head mounted proximity switches. Uniform size on each side of piston to eliminate different cushion seals and reduce spare parts

Smooth surface reduces cushion seal wear and provides air-tight accurate operation. Ideal for proximity switch applications. - Piston Seals

80 durometer, rounded lip, prelubricated, carboxylated nitrile U cups. Resists abrasion; when used with Peninsular’s internal lubrication system, provides considerably less wear and increases operating life. - Cushion Seals

90 durometer floating check type Urethane seals eliminate ball checks and related parts. Low friction breakaway and airtight cushioning

assures smooth maximum effectiveness. - Ports

NPT standard, metric and other thread size options. - Optional Proximity Switch Capability (Not Shown)

Allows for non-contact piston position sensing at near end of stroke. Precision machined cylinder heads and piston cushion hubs allow for

mounting of “RF inductive” proximity switches using the same switch probe length at each cylinder end without shims or spacers underneath

the switch. Self-contained switch probe not subject to contamination. This creates the same air gap between the sensing probe and target

(cushion hubs), thus providing consistent, reliable and repeatable stroke-to-go. Eliminates the design and construction of brackets

necessary to mount mechanical limit switches. - Optional Piston Magnet (Not Shown)

Tie-rod mounted reed switches can sense high gauss, “rare-earth material” magnet, anywhere along the cylinder stroke. Stronger magnetism

outside of the cylinder tube insures actuation of the reed switch. Tie-rod mounted reed switches sense strong magnetic field provided

by magnet in aluminum piston, allowing piston rod location to be determined wherever external switches are placed.